Background

In 2005, my father gave me a vintage Rivett 608 lathe that had been floating around my small town for some time. The serial number is 102 which, along with other markings, dates it to 1922. The local preist had this lathe and another in his pocession for as long as I can remember and he ended up giving it to my father sometime in the 1980's. Dad used it very little but was unable to pass up a free tool. After sitting in our basement for sometime, a neighbor expressed an interest in it and so it was moved next door for many years. He used it from time to time and cleaned it up some. After my neighbor passed away it sat for sometime in a shed which caused some rust to pit the surface in different spots. It finally found it's way back to our house and continued to sit in the basement.

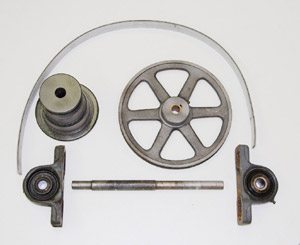

Eventually, I expressed an interest in it and it found its way to my home. I disassembled it completely down to every bolt, cleaned everything and reassembled it with the intention of putting it to work. There were some key pieces missing, most notably a majority of the change gears and a small idler gear that ran the power crossfeed. However, I was fully expecting to come up with these pieces over time and put it to work on my many hobbies.

However, in the meantime, I received a 13" South Bend lathe that was complete with all the accessories I wanted, and I really didn't have the time or space for both, so I've decided to part with the Rivett lathe. The extra size of the South Bend would be useful in future projects so it got to stay.

The Lathe

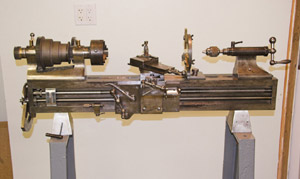

The lathe is an early Rivett 608 which dates from 1922 and uses 4NS collets in its spindle. I recieved it with a set of cast iron legs that it sits on but it obviously it is in need of a solid table top. The lathe has obviously seen some use in its life as there is some bed wear and the backlash in the cross slide and compound screws is approximately 0.040" and 0.025" respectively. The screws are 3/8" x 10tpi acme thread and I was planning on replacing them with some precision leadscrew available from McMaster-Carr.

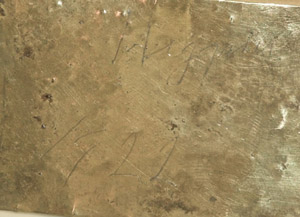

The serial number of the lathe is 102 which I initially deduced to be manufactured in 1922 due to a document I found listing 608 serial numbers manufactured for each year. Additionally, I was suprised to find later during disassembly that one of the Rivett workers scribed his name and year on the back of the change gear plate prior to assembly. I can't quite make out the name. Appears to be something like 'Higgins', but 1922 was quite legible as shown in the right photo above.

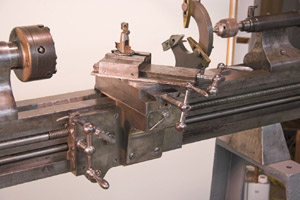

The main lead screw appears to be in very good condition. I don't see any wear on it. The left photo shows a close-up of the screw in the area that would have received the most wear when cutting threads. Since the lathe has a separate feed screw for carriage movement it was probably not used that much. Looking at the right photo above, it is appearant that at sometime in its life, the bed was re-machined. The dovetails on the front face was re-machined shown by the cutter swirl marks along with an additional shim added in the carriage's gib.

The left photo shows the movable gear used to engage and disengage the threading lead screw. The carriage feed screw does work along with the clutch mechanism to move the carriage. The lathe is equiped to provide powered cross feed but a small idler gear is missing from the cross slide that needs to be replaced. It should be a fairly simple gear to make if one has a mill and dividing head. The right photo shows the location of the missing gear.

The carriage stop is present but looking at the headstock end, it is appearant that the gear train is in need of some work. From photos I've found, it appears that the headstock would have originally had a gear on the spindle just inside of the rear headstock bearing. This would drive a short shaft through the headstock just below the spindle bearing out to a gear train. The three small closely spaced drill holes in the end of the headstock point to a reversing tumbler that is no longer present. The gear train would have moved from the reversal tumbler down to change gears on the banjo and on to the feed screws. At sometime, someone brazed a gear onto a hub and attached it to the back of the spindle with a key and setscrew. The remaining gears were held onto the banjo with makeshift carriage bolts. The change gears are plain 24 DP gears that one could make fairly easily or have custom made. There may even be off-the-shelf replacement gears. The original change gears are 7/16" thick.

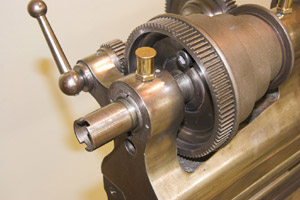

Here you can see the makeshift spindle gear attached to the spindle. I've often wondered if this was the originall gear that use to be on the spindle but on the other side of the bearing.

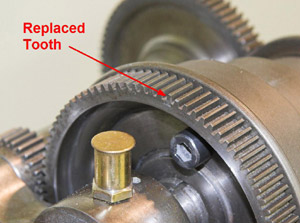

The spindle bearing seem to be in very good shape and can't detect any play in the spindle. It is tight but will coast for several revolutions after one gives the chuck a spin by hand. The back gear works and likewise feels nice and tight in its operation. There is, however, two teeth in the backgear train that have been repaired. the bull gear on the spindle has a tooth replaced as shown in the left photo and the large gear on the back gear has a tooth either repaired or replaced by brazing and then filing it to shape. I can't detect any binding or misalignment when spinning the spindle with the backgear engaged. I'm sure it would operative perfectly for as long as would use it.

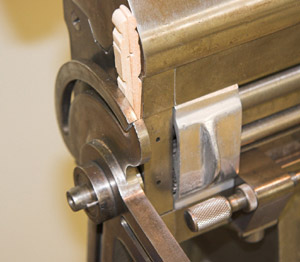

The banjo for the change gear does have a crack in it that I highlighted by using a wood wedge to open up the crack. Normally the crack is pretty tight and I would expect a decent welder could quickly fix it. The headstock does except 4NS collets and the inside taper is smooth with no nicks or burrs.

Six of the change gear have survived including the 120T & 60T compound set. The other 4 gears are 150T, 78T, 72T and 48T gears.

A view of the tailstock on the end of the lathe and the bed end plate with the Rivett name stamped on it. Just in the bottom of the right photo you can see the lathe's base with a brass nameplate for what i assume was the original seller when the lathe was new. The nameplate says, 'Blackman, Hill & McKee Machinery Co., St. Louis, Mo'.

Some views of the tailstock. The tailstock operates very smoothing and the locks work very well. The serial number is stamped on the bottom indicating it is the original tailstock. The inside taper is a Rivett proprietary dimension. The Jacobs chuck fits this taper.

Accessories

I got the lathe with two chucks and an faceplate that has never been threaded. The chucks are both 3 jaw scroll chucks.

The better of the two 3 jaw chucks is mounted to the original backplate that came with the lathe, it has the serial number stamped on it. The chuck is stamped, "The D. E. Writon Machine Co. New London Conn. U.S.A". The chuck works but I've never tried to assess its accuracy or precision.

The second three jaw chuck appears to be have seen better days. It doesn't have a backplate and thus I never attached it to this lathe.

The 6 inch face plate has no markings on it and has no threads cut in it. It does however appear to be possible to cut the correct size threads and use it on the lathe as the hub is the right dimensions.

The steady rest is in very good shape. One of the jaws was replaced at some time with an aluminum substitute as seen in the photos.

There are also 6 4NS collets that I've collected over time. There is no collet closer so it was to be one of my first projects for the lathe once it was running.